As Indian furniture, be it in any kind of solid wood is extremely popular in Indian & the World over, it must go through a thorough treatment before it is crafted into a piece of furniture. Before the manufacturing starts it goes through the Seasoning & Chemical process, as explained below

Seasoning Process

Depending upon the weather, the wood is kept in a seasoning chamber. In winters we season wood for a period of 13 to 16 days & in summer the wood is seasoned for 7 to 10 days. The moisture level is brought down to a level of 5 to 9 % so when an Indian solid wood piece of furniture is made in a manner that it retains it sturdiness & can withstand most kinds of weather.

Chemical Process

As Indian furniture manufactured in Jodhpur, Rajasthan is exported to various countries, the norms for chemical treatment of wood for furniture made by the manufacturers is extremely strict.

Keeping that in mind, chemicals like biflex – terminator & ccb are used in the chemical chamber in which the wood is kept for a period of 2 hours. This ensures that the wood is completely termite free & the furniture manufactured from it can be used in Indian weather as well as exported to various countries in the World.

Process of Manufacturing

Step 1 : Surface Planner

The piece of wood is first cut horizontally. This measurement is more or less approximate in order to assemble all the planks to make the piece of furniture. The lengths of wood are sorted out depending on whether it is dining furniture or living room furniture as all require different lengths as the initial cutting is done as per the required sizes.

Step 2 : Thickness Planner

Once the initial cutting of the wood is done. The thickness of the wood has to be set correctly. Depending on the piece of furniture being made & whether it is sheesham wood, mango wood or teak wood, the thickness could vary as different woods have a different kind of look & in some a certain thickness may look better on a certain wood than the other.

Step 3 : Trolley cutter

The trolley cutter is used for rough cutting which could be for smaller parts of the furniture such as drawers , small doors etc which is again before the furniture is assembled.

Step 4: Clamping

As most furniture today is made in joints, the planks have to be clamped before the furniture is made. This is where the adhesive used is extremely important in order to ensure the joints remain intact & the movement is minimized as far as possible. This is extremely important for large surfaces such as dining table tops, living room sideboards etc.

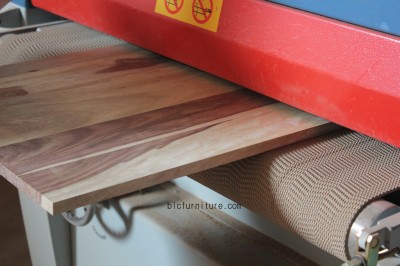

Step 5 : Sanding

The Sanding of the wood is what ensures that the finish is smooth once the furniture is made. The wooden plank is passed through the sanding machine. This machine saves the trouble of doing finishing by hand which would be a much more tedious & time consuming process comparatively. A good sanding machine such as the one used would make the top absolutely smooth.

If required the plank of wood is sanded repeatedly in order to achieve the even finish.

Step 6 : Panel Saw

In order that the furniture retains a neat look with even borders, clean cuts & proper finishing on the edges & give it a machine made look it is finally cut with a panel saw machine. We use a felder panel saw machine which gives it a completely even look. As any solid wood furniture tends to have movement it is important that the furniture has a straight line look especially when it comes to wooden cabinets, wooden cupboards, corners & edges of sheesham wood dining tables etc. A good Panel saw machine will give sheesham wardrobes & sliding wardrobes the required machine made look that is required in a piece of furniture today.

Once the approximate sizes of planks of wood are cut , depending on the requirement as to whether it is a wooden dining table, sideboard or cabinet, it comes to the precise measurement & cuts down to sizes required. If the place is small for furniture manufacturing, vertical panel saw’s can also be used. As the furniture tends to have large volume & the wood pieces tend to be large, horizontal panel saws work better in manufacturing furniture.

Note: Although every precaution is taken to ensure that a fine piece of furniture is manufactured, please take into consideration that wood being a natural & organic product will always have moisture in it & can have movement if it is subject to variations in weather condition. However the beauty of wooden furniture is that it can always be rectified & re furbished to make the furniture look new again.

Further minor blemishes, variation in colour, irregular grain etc are all a natural part of the character of Indian Furniture & should not be considered a defect of any sort.

I would like to see pictures and cost of product such beds with storage,wardrobes and bed side tables.

I would like to see pictures and cost of product such beds with storage,wardrobes and bed side tables.

Hi,

Could you please help with your views on handheld sheet sander to do sanding?

Do you guys use it?